Choosing the right replacement parts for your Eames Lounge Chair requires more than just finding a compatible fit....

China office chair caster wheels factory manufacturing process

Here below pictures are for the office chair wheels factory manufacturing process:

Mold workshop for office chair wheels caster

Chair Casters wheels can be used for a wide variety of applications, It is important to have the right caster for the right application, the right size caster will be the difference between having a working application to not working at all.

Our office chair wheels diameter was available from 25 mm to 100 mm with locking casters& unlocking casters(swivel casters)function. The width of office chair casters is available is from 28mm to 73mm. The height of office chair casters is available from 32mm to 111.5mm.

This picture shows you our different molds for chair caster wheels.

Injection workshop for office chair wheels caster

As you know the chair wheel caster includes Steel Hardware and polymer(people also named plastic, nylon, PVC, PU caster wheels)

In the injection workshop, our production line did the Polymers and Polyurethane part of caster wheels.

Caster wheel injection from a blend of Polymers and Polyurethane forming a one-piece design that is solid and will not de-laminate. Polymers and Polyurethane Caster Wheels are great for wet and corrosive environments while providing a high impact resistant wheel. Polymers and Polyurethane caster wheels are more economical compared to a Phenolic Wheel or a Steel Wheel. These caster wheels are not affected by chemicals, solvents, oils, blood, grease, and will not absorb water. These caster wheels are non-marking and light in weight. Black is the standard color on plastic wheels. White,gray,red,green,blue,yellow color are available for customization.

Castor wheel boiling is to increase its toughness, if it is not boiled, the caster and wheels are easy to break, The sound is crisp when you knock on casters and wheels

So it is necessary to boil the caster wheels and bracket after mold injection.

This picture shows you our Injection workshop for caster wheels.

Hardware workshop for office chair wheels caster

In the hardware workshop, our production line did the Steel part of caster wheels.

Our caster wheel has 5 series hardware, they are Top plate, Grip Ring stem, Grip Neck Stem, Threaded stem, U-Bracket.

Grip Ring stems regular diametsilence grip ring er approx 7/16″equal to 11mm. regular length approx 0.826 inches equal to 21mm.

Grip Neck Stem regular diameter approx 5/16″equal to 8mm , regular length approx 1 1/2″equal to 38mm.

Threaded stem diameter 1 is approx 1/4 inch equal to 6mm which is called M6 threaded stem caster wheel.

Threaded stem diameter 2 is approx 5/16″equal to 8mm which is called M8 threaded stem caster wheel.

Threaded stem diameter 3 is approx 0.4 inches equal to 10mm which is called M10 threaded stem caster wheel.

U-Bracket Stems are for use on ready-to-assemble furniture such as office chairs, printer stands, computer desks, and entertainment centers. U-brackets measure 11/16 in. inside diameter equal to 18mm.

This picture shows you our Hardware workshop for caster wheels.

Assembly workshop for office chair wheels caster

After Polymers Polyurethane parts and hardware stem finishing, our workers operate the assembly machine to install each piece of caster and wheels.

These pictures show you our Assembly workshop for office chair wheels caster.

Quality test for office chair castor wheels

Test purpose: to evaluate the compressive strength such as the impact of office chair casters wheels and control the quality of products.

Impact Test standard: ANSI/BIFMAX5.1

Technical specifications: Slowly load to 11120N(1134KGS), hold for 1 minute, and release the force; then slowly load to 11120N(1134KGS) for 1 minute again, and record the test process.

Impact Result evaluation: According to the standard operation, the chair base has no abnormality and does not break when the force is increased to 11120N(1134KGS), which meets the standard requirements.

Life cycle testing, reliability testing, or accelerated life testing is an important aspect of the research and development process for caster wheels and materials.

The main purpose of such testing is to study the effects of long-term usage of materials to determine breaking points, wear locations, functionality failure, and more.

We utilize robot or custom test rig facilitated testing to monitor and control parameters to determine reliability, durability, and life cycle. These factors together are what allow us to understand the reliability of the caster wheels.

These caster wheels reliability tests are what ensure the reliability and durability of your product throughout its lifecycle.

Salt spray testing provides a controlled accelerated corrosive environment to evaluate the relative corrosion resistance of the coating, substrate, or part itself. Parts or panels are placed inside a chamber and exposed continually for a specified period of time, then evaluated for resistance to corrosion. This type of testing is also known as salt fog testing.

Packing for office chair castor wheels

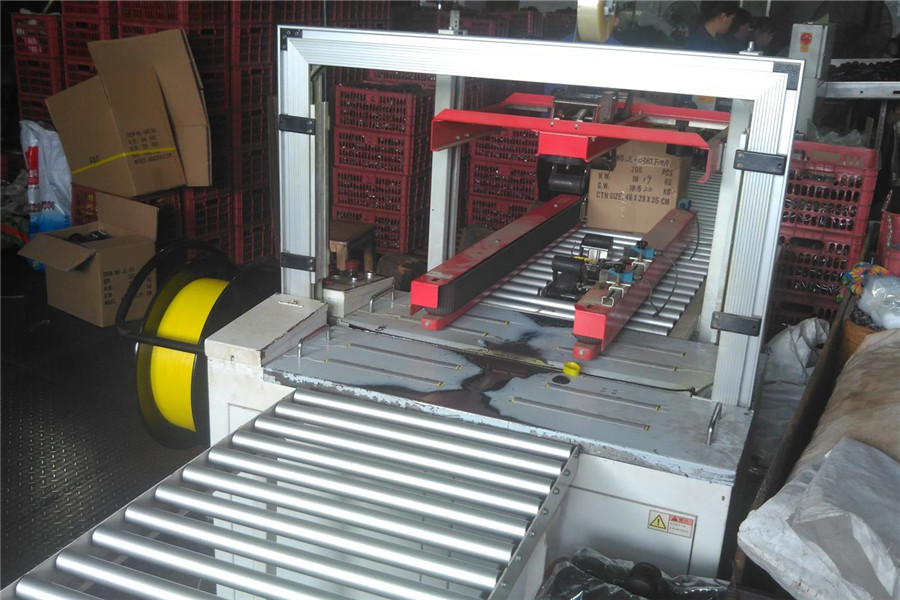

The last manufacturing process is packing.

With helping of workers, The wrapping machine finishes the caster wheels package into a PP bag usually 5 pieces caster wheel per set, it can be packed 4 pieces castor wheel per set if you request.

In the next, after workers put castors into a standard carton box, The wrapping machine will finish the seal.

In the end, All the finish caster wheels will be saved at the warehouse waiting for the loading container.

Latest comments