Our office chair parts include 5 series:

1.office caster wheels

2.office chair bases

3.chair gas lift cylinder

4.chair mechanism

5.chair armrest

Please keep reading for each spare parts measurement guide below:

1.office caster wheels

Office chair Casters wheels can be used for a wide variety of applications, It is important to have the right caster for the right application, the right size caster will be the difference of having a working application to not working at all. Taking key measurements will ensure that the caster will fit for the application. The following are 4 areas to measure.

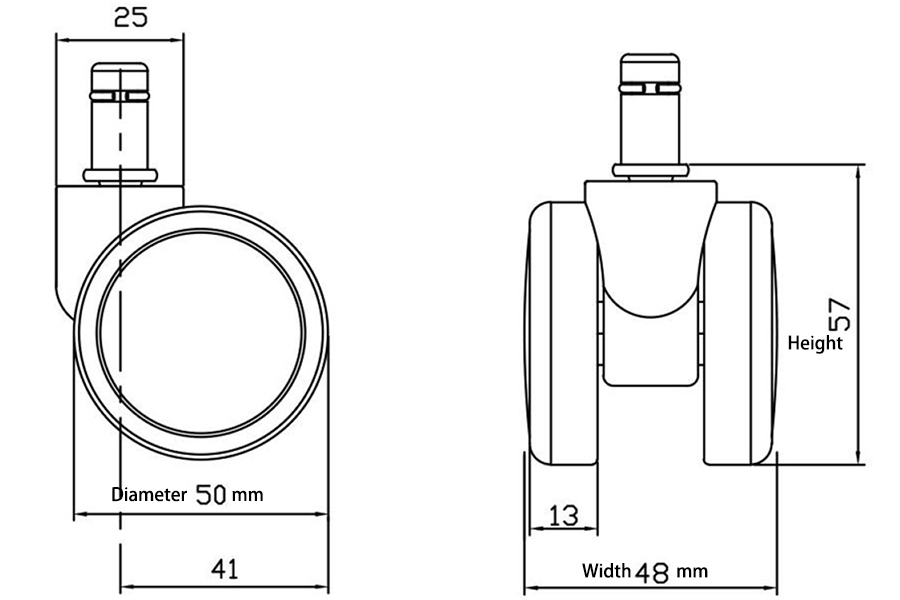

Diameter for office chair casters wheels

Office chair casters wheels including swivel casters and stable casters

swivel casters diameter measurements can be important in many applications as it provides important information as to how much clearance you will need for your caster to swivel. The goal for a swivel caster is to be able to swivel 360 degrees.

To determine your Swivel caster diameter, lay the caster down on its side and measure from the center of the kingpin to the back edge of the wheel. A straight edge lying up against the face of the wheel will make it much easier for you to determine this measurement; the point where the tape measure meets the straight edge will determine your Swivel casters diameter.

Overall Height for office chair casters wheels

How to measure the overall height of the entire caster assembly? from the very bottom of the office chair caster wheel to the very top of the Chair mechanism. This is simple enough; just lie the castor on its side and take the measurement. Again, write these numbers down and be sure they’re appropriately labeled.

Width for office chair casters wheels

This is often called the tread width. It represents the width of the wheel face, measured without a load present.

How to measure the for office chair casters wheels width?stand the for office chair casters wheels upright and measure from the outside of one side to the outside of the other.

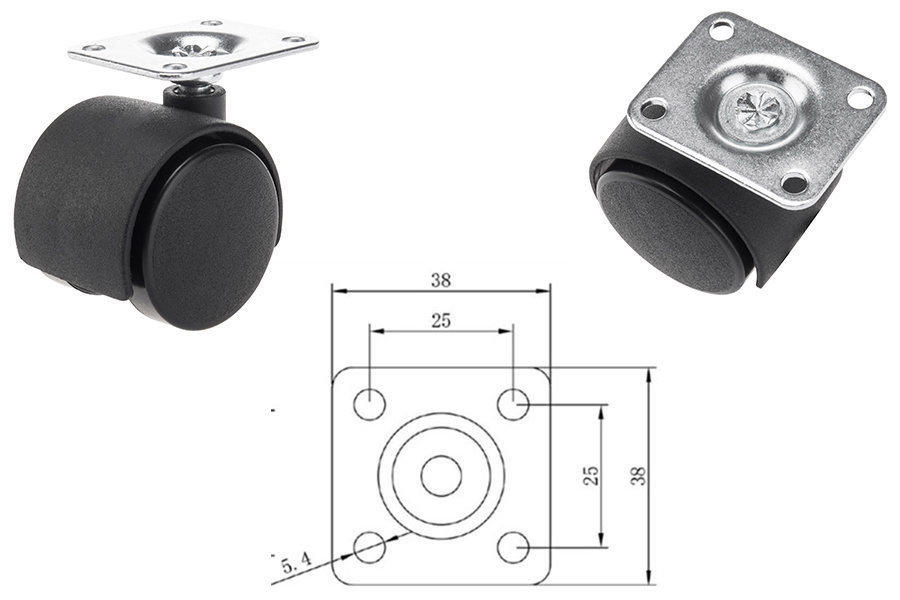

Top plate style Caster wheels

The top plate is used to attach the caster to the object, whether that object is a cart, rack, or even a piece of furniture. top plate are available in various sizes, so it’s important that you measure it properly to ensure that your replacement caster fits. Measure both the length and width and write these down.

For most applications, it is very difficult (or impossible) to change the bolt hole pattern on the object that the caster will attach to. For this reason, you will need to measure the bolt hole pattern very carefully and ensure you get a perfect match. To do this, measure from the center of one hole to the center of the other lengthwise, and then repeat this process again widthwise. Take note of these measurements.

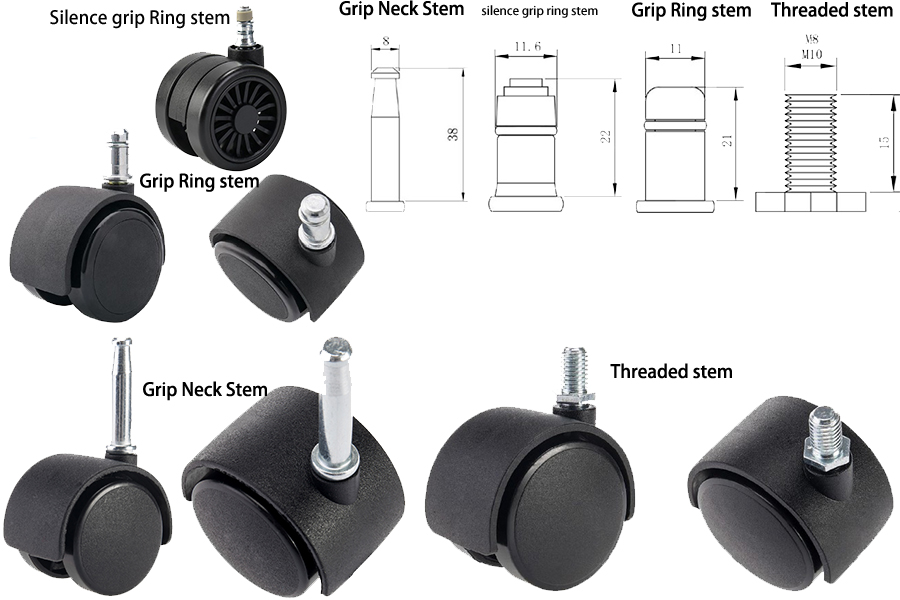

Stem Style Caster wheels

Stem caster wheel including Threaded stem, Grip Ring stem and Grip Neck stem

Use a ruler to measure from the top of the stem to the base plate and Overall length of stem.

You can also use a standard set of wrenches, for instance take a 7/16”. Use the open end of the wrench and put it on the stem, it should be a snug fit. Always measure the widest area.

Adjustable Wrench: Tighten the adjustable wrench around the widest part of the stem. Then take a ruler and measure the distance of the wrench opening.

If you have a caliper, measure the stem in the section below the ring toward the caster body using your caliper.

Grip Ring stem and silence grip ring stem regular diametsilence grip ring er approx 7/16″equal to 11mm . regular length approx 0.826 inch equal to 21mm

Grip Neck Stem regular diameter approx 5/16″equal to 8mm ,regular length approx 1 1/2″equal to 38mm

Threaded stems:

The diameter approx 1/4 inch equal to 6mm which called M6 threaded stem caster wheel.

The diameter approx 5/16″equal to 8mm which called M8 threaded stem caster wheel.

The diameter approx 0.4 inch equal to 10mm which called M10 threaded stem caster wheel.

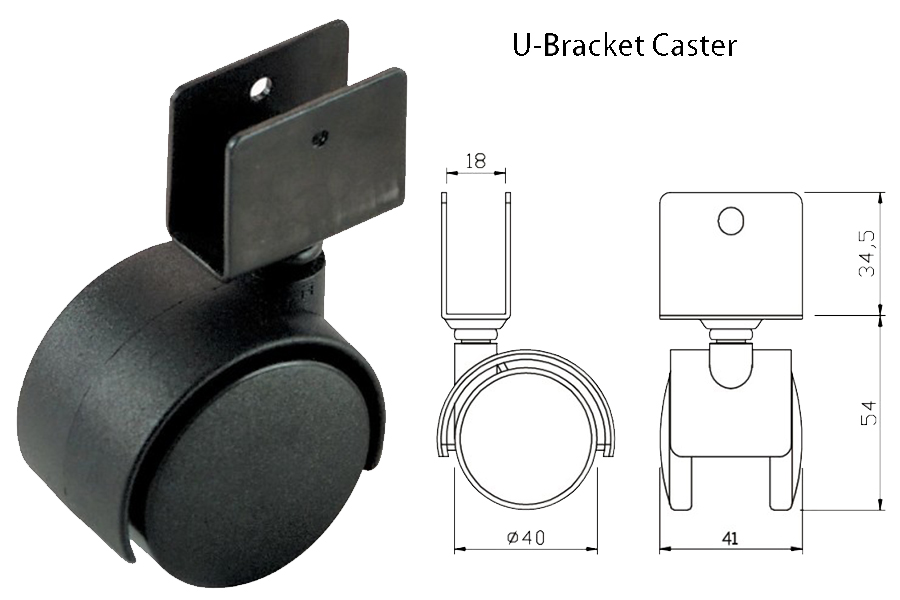

Special Design U-Bracket Caster

These caster wheels are for use on ready-to-assemble furniture such as office chairs, printer stands,computer desks and entertainment centers.U-brackets measure 11/16 in. inside diameter equal to 18mm.

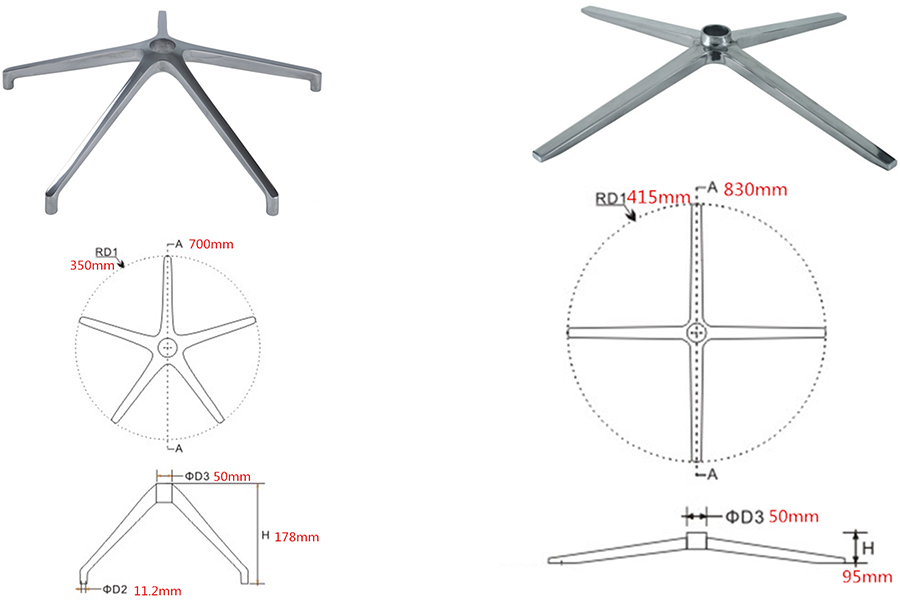

2.Office chair bases

Need help figuring out what size chair base you need?

First confirm you have a standard chair base, If the base center hole is 2" in diameter which equal to 50mm, you have a standard chair base

To find chair base diameter, measure center hole and radius,Then Multiply the length of radius and add center hole

To find chair base height, measure from floor to the top level of chair base.

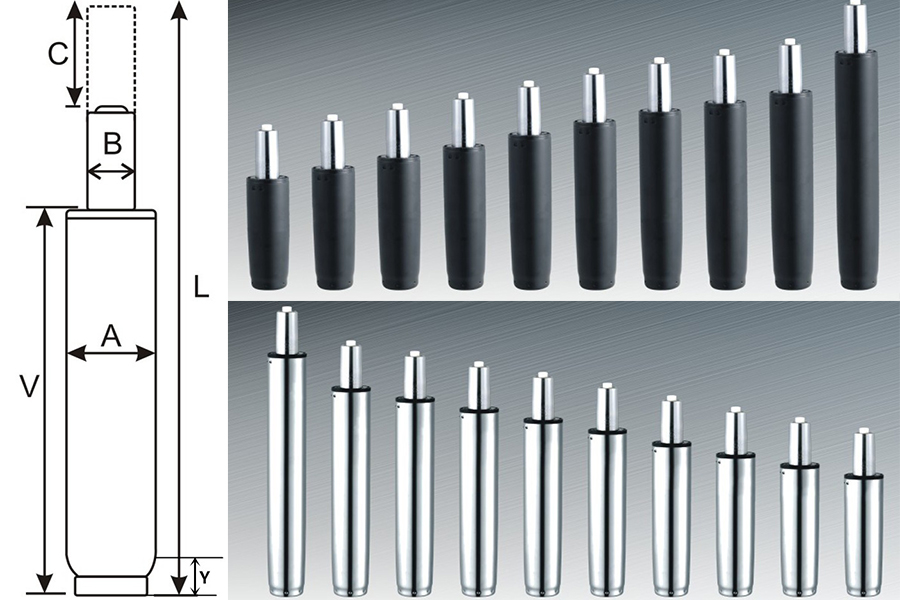

3.chair gas lift cylinder

Our office chair gas lift cylinders are typically universal. The only difference between all standard cylinders is what height they make your seat.

First confirm you have a standard cylinder, If this column is 2" in diameter which equal to 50mm, you have a standard cylinder.

Be sure to measure as shown in below photo A (do not measure the underside)

Determine Cylinder Travel in below photo C.

Find the seat height with the seat all the way up and all the way down. The difference between the two is the travel.

Finally, select the closest cylinder to your travel

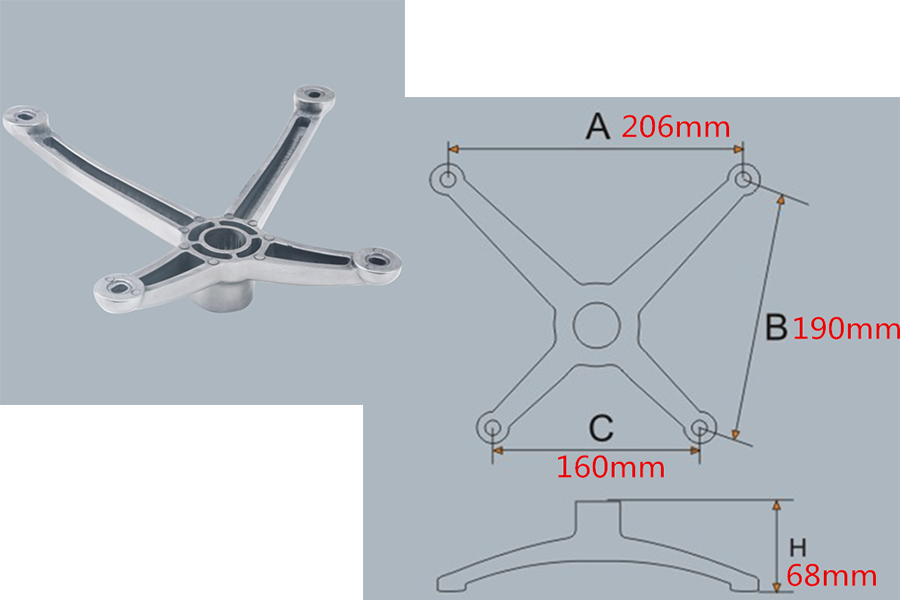

4.chair mechanism

The Chair mechanism is used to attach the chair gas lift cylinder to the object, whether that object is a stool,a chair. Chair mechanisms are available in various sizes, so it’s important that you measure it properly to ensure that your replacement mechanisms fits. Measure both the length and width and write these down.

For most applications, it is very difficult (or impossible) to change the bolt hole pattern on the object that the mechanism will attach to. For this reason, you will need to measure the bolt hole pattern very carefully and ensure you get a perfect match. To do this, measure from the center of one hole to the center of the other lengthwise, and then repeat this process again width wise. Take note of these measurements.

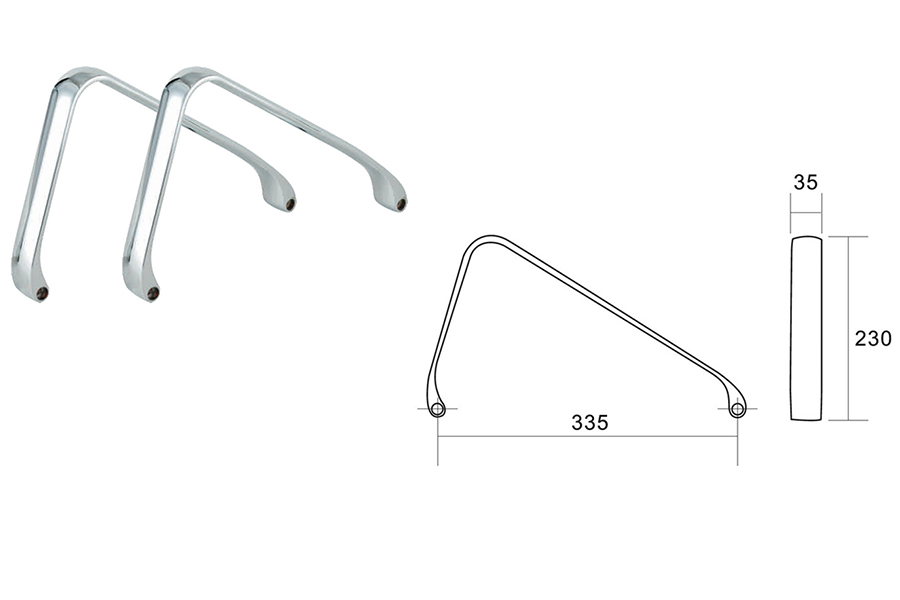

5.chair armrest

The chair armrest is used to attach the chair seat to the backrest,it’s important that you measure it properly to ensure that your replacement armrest fits. Measure both the length and width and write these down.

For most applications, it is very difficult (or impossible) to change the bolt hole pattern on the object that the armrest will attach to. For this reason, you will need to measure the bolt hole pattern very carefully and ensure you get a perfect match. To do this, measure from the center of one hole to the center of the other lengthwise, and then repeat this process again widthwise. Take note of these measurements.